The problem of choosing a hydraulic motor

Some of the key parameters to consider when choosing a hydraulic motor are:

- Oil pressure

- Maximum oil consumption

- Minimum and maximum rotation range

- Maximum torque

- Proportionality of steering angle and oil consumption

It is also worth paying attention to the type and size of the hydraulic motor, as well as operation in high temperatures or other adverse conditions that may affect its performance.

An important aspect when choosing a hydraulic motor is to compare different manufacturers and models in order to choose the most suitable option for a specific task in terms of price-quality ratio.

So, when choosing a hydraulic motor, it is necessary to take into account many parameters in order to select the most suitable model, taking into account not only the technical, but also the financial aspects of the mechanism.

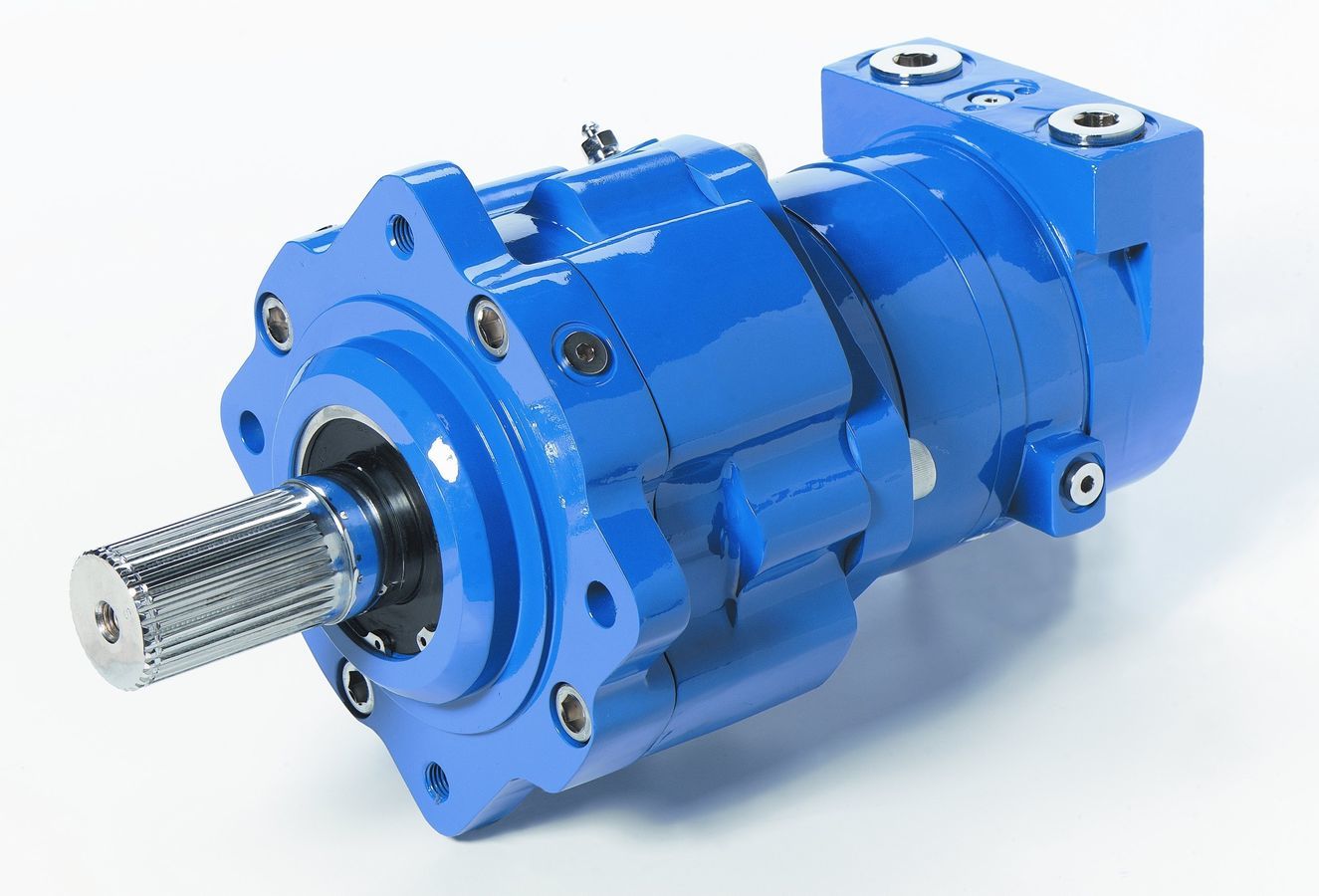

— Rotary hydraulic motors.

Rotary hydraulic motors are hydraulic drives that are used in many industrial and manufacturing applications. They can handle both small and large volumes of liquid and provide high efficiency.

— Valve hydraulic motors.

In the world of hydraulic equipment, hydraulic motors play an important role in the movement of machinery that drives various industrial processes. They are devices that convert hydraulic energy into mechanical energy, which allows them to drive a variety of industrial equipment. A key component of a hydraulic motor is its valves, which regulate fluid flow and ensure optimal operation of the device.

— Plunger hydraulic motors.

Plunger hydraulic motors are one of the most common types of hydraulic motors that are widely used in various fields of industry and technology. They are hydraulic devices that use surrounding fluid to transmit torque to a shaft.