Oil pump: gear, rotary, gerotor (with internal and external motor), piston, vane vane

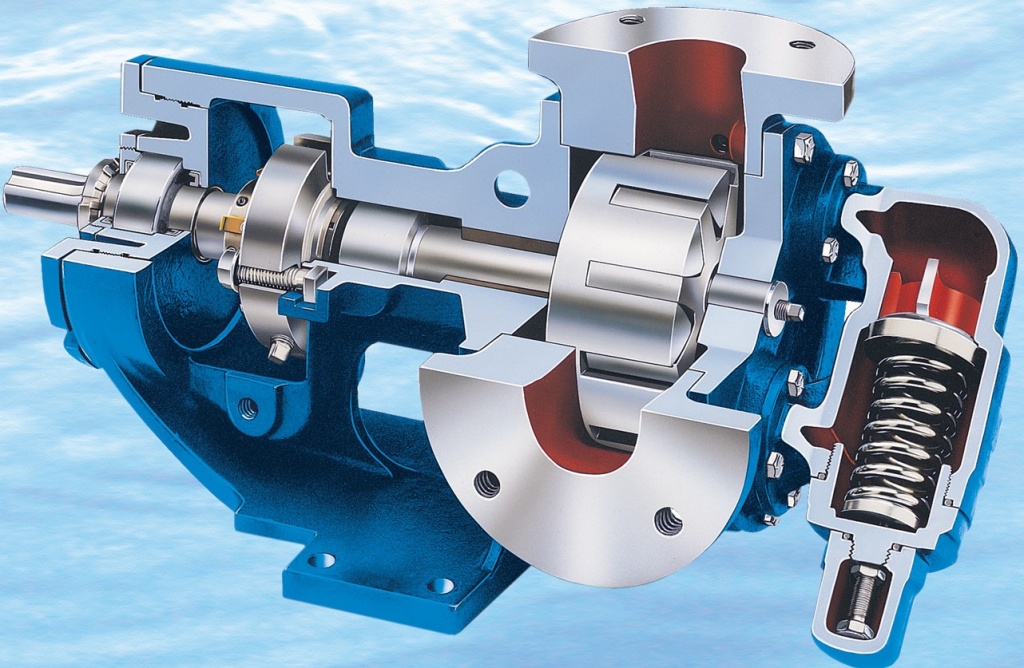

Oil pumps in the system can be gear, rotary, gerotor (with internal and external motor), piston, vane vane. The most popular are gear models.

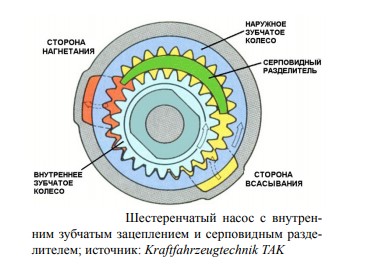

In practice, gear models show themselves to be the most productive. The design of gear pumps varies greatly. In transport, structures can be installed where gears are located side by side (external gear solutions) and inside each other (gear within a gear), i.e. gearing is internal.

Pumps with external gears are more compact (they can be easily placed in a limited space) and wear-resistant due to the low sliding speed in the mesh and, accordingly, low pressure on the teeth. And these are their significant advantages over external gear pumps. However, most manufacturers produce pumps with external gearing. The gear-in-gear design is more expensive because it is more complex to implement, and the manufacturer cannot guarantee the same efficiency as in the case of an external gear solution.